IST,

IST,

Competitiveness of India's Manufacturing Sector: An Assessment of Related Issues

|

L. Lakshmanan, S. Chinngaihlian and Raj Rajesh* This paper provides an analytical abstract of various parameters of manufacturing competitiveness of the Indian economy. India's manufacturing exports have risen impressively in the past decade or so and found to be directly linked to the world GDP and inversely related to real effective exchange rate (REER). Indian manufacturing industries have certain inherent strengths and advantages in having a relatively inexpensive, adequate and skilled labour force, cost-effective and competitive prices of goods produced, large manufacturing base and proximity to fast growing Asian markets. India is one of the leading producers and exporters in a number of commodities and enjoys significant advantages in terms of lower labour costs as compared to other economies. Nevertheless, India's competitiveness is lost on account of lower labour productivity and higher input and material costs. To improve the competitiveness of the Indian manufacturing goods, issues like further diversification of export basket, upgradation of export quality, improvement in productivity, increased technology intensity in production, enhanced R&D activity, encouraging business environment, less cumbersome regulatory environment, flexible labour laws, removal of infrastructural bottlenecks and SME related issues need attention of all concerned. JEL Classification : F 230, L 150, L 600, O 570 Keywords : Manufacturing sector, Competitiveness Introduction Sustained increase in competitiveness of an economy is a hallmark of economic strength and stability of that economy. Worldwide, there has been an increasing awareness, especially among emerging market economies (EMEs), about the need to strive for improved competitiveness to face the realities of the globalised trading environment. In the case of India, such recognition is reflected during the recent years, particularly in the constitution of National Manufacturing Competitiveness Council. At the current juncture, the Indian economy is at the threshold of entering the big league through a crucial turnaround in its performance. Such a turnaround has been reshaping India's image as one of the emerging economic powers in the world. India has recognised the opportunities stemming from globalisation and accordingly revamped its policies to promote industry and services sectors. India's ability to compete on the global stage is amply demonstrated by the boom in information technology and software services. India has emerged as a destination for outsourcing of not only information technology enabled services (ITES) but also a host of other services including certain manufacturing activities such as automotive components, pharmaceuticals, textiles, etc. India is fast establishing its image as a competitive economy the world over, which assures low-cost and high-quality products. In the recent years, it has achieved certain landmarks in the manufacturing sector. Amongst them, the most important has been the rise of Indian MNCs, which have been on expanding mode and acquiring companies abroad and developing their production base in other countries. In addition, Indian firms are exporting services ranging from call centres to medical diagnostics and tutoring American high school students. In this backdrop, Indian economy could be larger than all the countries in the world other than the US and China in another 30 years and India's growth will remain above 5 per cent through the period (Goldman Sachs, 2003). Against this setting, this paper makes a modest attempt to assess the competitiveness of India's manufacturing sector, its relative position among the countries of comparable economic size, its strengths and vulnerabilities, the issues to be addressed to strengthen India's competitiveness and to suggest some policy preferences. The scheme of the paper is as follows. Concept and benchmark indicators of competitiveness based on some literature survey is presented in Section I. Section II analyses the dynamics of India's manufacturing sector exports. Section III critically evaluates India's manufacturing sector competitiveness based on specific factors like openness, unit labour cost, labour productivity and national innovative capacity. A micro-level analysis on the competitiveness of select manufacturing commodities of export importance for India has been set out in Section IV. Section V identifies the critical issues faced by the Indian manufacturing sector while competing in the global market and suggests some measures to improve India's competitiveness. Concluding observations are drawn in Section VI. Section I Concepts and Benchmark Indicators of Competitiveness At micro level, it is relatively easy to define competitiveness of a firm, which is the ability to do better than comparable firms in sales, market share or profitability; but competitiveness of a country is interpreted broadly on development or growth strategy. However, a narrower, more tractable, definition is to take the country's ability to compete in international trade. Thus, a country may be termed competitive if it is able to sell its products at a lower (or same) price and earn the same (or higher) return as its competitors. Variables such as remuneration of factors of production, exchange rate and productivity through the use of better technical skills and human resource development as also economies of scale are having greater influence in deciding the extent of competitiveness of export products in the globalised setting. OECD defines competitiveness as the degree to which a nation can, under free trade and fair market conditions, produce goods and services, which meet the test of international markets, while simultaneously maintaining and expanding the real incomes of its people over the long-term. The World Economic Forum (WEF) defines competitiveness as the ability of a country to achieve sustained high rates of growth in GDP per capita. According to National Competitiveness Council (in USA), competitiveness is the ability to achieve success in markets leading to better standards of living for all. According to it, competitiveness is a concept that is important at a range of levels, from the level of an individual firm to the level of an industry, from the level of a small local region to the level of an association of nation states. The concept of competitiveness, thus, can contribute to an understanding of the distribution of wealth, both nationally and internationally, if it is recognised that it can be applied at both the enterprise and the country level; when applied at the enterprise level, it relates to profits or market shares; when applied at the country level, it relates to both national income and international trade performance, particularly in relation to specific industrial sectors that are important in terms of employment or productivity and growth potential (UNCTAD, 2004a). Benchmark Indicators and Competitiveness of the Indian Economy There are two leading surveys on competitiveness at global level that document competitiveness of economies on a regular basis, viz., Global Competitiveness Report [by the World Economic Forum (WEF), Switzerland] and World Competitiveness Yearbook [by International Institute for Management Development (IMD) of Lausanne, Switzerland]. The WEF first introduced Global Competitiveness Report 2001-2002 in 2002, which has since then become an annual publication. The report uses two concepts of competitiveness: Global Competitiveness Index (GCI) and Business Competitiveness Index (BCI). The GCI aims specifically at gauging the world's economies in achieving sustained economic growth over the medium to long-term. Three indices are used for computing GCI, viz., the macroeconomic environment index, the public institutions index, and the technology index. BCI complements the GCI, with its special emphasis on the underlying microeconomic conditions defining the current sustainable level of productivity in each of the countries covered. The underlying concept being that, while macroeconomic and institutional factors are critical for national competitiveness, these are necessary but not sufficient factors for creating wealth. Wealth is actually created at microeconomic level by the companies operating in the economy. The BCI evaluates two specific areas, which are critical to the business environment in each country - the sophistication of the operating practices and strategies of companies, and the quality of the microeconomic business environment in which a nation's companies compete. In terms of global benchmarking parameters, Global Competitiveness Report 2006-2007 has ranked India at the 43rd position among 125 economies in terms of the GCI (Table 1). Thus, India has moved two steps higher than the ranking received during 2005. The Indian economy has been progressively integrating with the global market since the initiation of economic reforms in the early 1990s. This has facilitated substantial improvement in the competitiveness of the economy. According to GCI, Singapore, Korea, Malaysia and Thailand are more growth competitive than India. India received significantly higher rankings with regard to Business Competitiveness Index at 27th amongst 121 economies, recording an improvement by 4 positions. India's business competitiveness as in 2006 was better than some of the EMEs such

as China, Mexico, Indonesia, Philippines and Russia, though it lagged behind other economies such as Singapore, Korea and Malaysia. According to the World Competitiveness Yearbook 2006, India ranked 29th among 60 major countries and regions in the world. This is 10 notches up from the 39th rank India achieved in the previous year (Table 2). As per the rankings, Singapore, Malaysia and China are more competitive than India. In addition to the overall competitiveness of economies assessed by the WEF and IMD, United Nations Industrial Development Organisation (UNIDO) also published in its annual report, the competitiveness of the industrial sector of a number of economies and their ranking. The UNIDO's Competitive Industrial Performance (CIP) ranking is a benchmark for industrial activity comprising four variables, viz., manufacturing value added per capita, manufactured exports per capita, industrialisation intensity and export quality. Industrial competitiveness ranking of a majority of the South East Asian countries are higher than India. India's rank has slipped down from 36 in 1990 to 40 in 2000 among the list of 93 countries (Table 3).

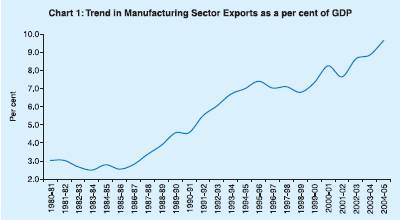

Section II The Dynamics of India's Manufacturing Sector Exports Before analysing the parameters that determine the competitiveness of the Indian manufacturing sector, it would be useful to understand the dynamics of growing export performance of the Indian manufacturing sector. Manufacturing exports dominate the export basket of the Indian economy and account for nearly 70 per cent of the total merchandise exports. The Indian manufacturing exports have risen faster since the Indian economy started opening up in the 1980s. The manufactured exports as a percentage of India's GDP has increased from 2.5 per cent in 1983-84 to 9.1 per cent in 2006-07 (Chart 1). The depreciation of Indian Rupee since the 1980s, along with liberalisation measures in the trade and exchange rate regimes have contributed to the growth of manufacturing exports of the country. Furthermore, growing integration with the world economy has also aided the expansion of the manufactured exports. It would be worthwhile to revisit the factors that have contributed to the growing exports of the economy.

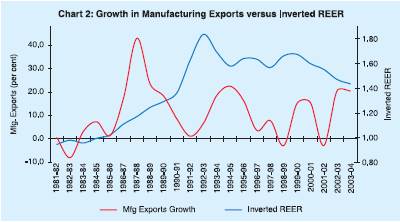

Several studies have established a significant relationship between export performance and the real exchange rate in India. Joshi and Little (1994) attributed a considerable part of the success in export expansion during the second half of the 1980s to the real exchange rate depreciation. They argue that the depreciation of the real exchange rate by about 30 per cent between 1985-86 to 1989-90 was a critical factor in driving India's exports. Srinivasan (1998) analysed India's exports over 1963-94 and found that real exchange rate appreciation negatively affects export performance. Besides exchange rate, global GDP has also been found to have a positive association with increasing exports of India. In the light of these studies, we would assess the role of these variables in driving India's manufacturing exports. To begin with, the role of Real Effective Exchange Rate (REER) in driving India's manufacturing sector exports is assessed. For analysing this relationship, we take inverted-REER, which is the reciprocal of REER. The inverted-REER eases the visual introspection so that an increase in REER reflects depreciation, while a decrease appreciation. The near co-movement of manufacturing sector exports and inverted-REER for most of the period (during 1980-81 to 2003-04), validates that REER has been one of the factors in determining our exports (Chart 2). The correlation between the manufacturing

exports and inverted REER is found to be high at 0.66. This indicates that change in REER significantly affects the manufactured exports. The years 2002-03 and 2003-04, however, appear to be aberrations, wherein the exports have increased despite the appreciation of the Rupee. This perhaps suggests that India's manufacturing sector exports are becoming more competitive in the global economy. Apart from REER, global GDP has also been found to be affecting the India's manufacturing sector exports. It is observed that for most of the period since 1980s, there has been a co-movement of growth in manufacturing exports and global GDP growth (Chart 3). During 1999-2000 to 2004-05, a significant correlation of 0.56 was observed between India's manufacturing sector exports and the global GDP growth, which suggests that the former has started depending upon the latter. We tried to estimate an empirical relationship among manufacturing exports, REER, and world GDP for the period 1980-81 to 2003-04 through a regression analysis using ordinary least squares (OLS). In the estimate, we found a relationship wherein the manufactured exports (dependent variable) depend positively on world GDP, and negatively on the real effective exchange rate. In the estimation exercise, the variables were log-transformed. A dummy

variable (DUM) was also introduced to capture the effects of devaluation of Indian Rupee (in 1991) on manufacturing exports. DUM assumes a value equal to 1 in 1991 and is 0 for the rest of the years. The estimated relationship is as follows:

LMFGXt = 0.45 LWGDPt - 0.37 LREERt + 0.71 LMFGXt-1- 0.15

DUM Adj. R2 = 0.988,

where, figures in parentheses indicate the t-statistics. LMFGX

= Log of Export Volume (expressed in US dollars) The results are on expected lines. Manufacturing exports were found to be positively associated with global GDP. The elasticity estimate suggests that a 10 per cent rise in global GDP enhances India's manufacturing exports by 4.5 per cent. The negative elasticity of export demand with respect to REER during the period implies that the real appreciation of the rupee adversely affects India's manufactured exports. Section III Measuring the Competitiveness of Indian Manufacturing Sector At a micro level, several studies have been made to assess the competitiveness of India's manufacturing sector. The CII and the World Bank jointly carried out a study in 2002 using various parameters such as investment climate (Government effectiveness, rule of law, graft, and political instability and violence); labour costs; regulatory regime; interest costs; energy costs; delays at custom houses, etc., to measure the competitiveness of the Indian manufacturing sector. For the present study, we have used the following parameters to make a comparative analysis of India's competitiveness vis-à-vis other economies of comparable economic size, particularly the Asian countries. A. Openness of the Indian Economy Openness of an economy can be related to its permissiveness towards cross border movement of goods, services and other factors of production. An increased openness implies higher trade flows and availability of wider range of goods and services to choose from, often at more competitive prices. Also, international trade and investment flows will increase the access to newer and more innovative technologies, which can, in turn, lead to productivity improvements. Trade openness of an economy has two distinct dimensions - ex-post openness and ex-ante openness. Ex-post openness of an economy refers to the actual inflow of imports and outflow of exports. Ex-ante openness of trade of an economy, on the other hand, relates to the permissiveness of its policy towards exports and imports like levels of tariff and non-tariff measures applied by the country on cross-border trade flows. We first begin with ex-post openness analysis, which is simply based on the actual trade flows such as the share of trade in GDP or the growth rates of imports and exports. Trade openness measured as the ratio of sum of exports and imports to GDP reveals a continuous increasing trend in India's trade openness since 1987-88. India's openness increased sharply from 15.7 per cent in 1990 to 31.8 per cent in 2003 in the aftermath of economic reforms in the country. However, when compared to other EMEs in Asia such as China, Korea, Malaysia, Thailand, Vietnam, etc., India was not found to be a highly open economy as its trade-GDP ratio is much lower. Even the average tariff rate in India is much higher than these economies. Nevertheless, in terms of economic freedom, when compared with other EMEs in Asia, India is found to be at par with these economies. In terms of investment flows as well, India has lagged behind many of these EMEs (Table 4). The ex-ante openness is measured by trade barriers. The direct measure of trade barriers includes inter alia average tariff rates or

coverage ratios for non-tariff barriers. India's customs tariff rates have been declining since 1991. The peak rate has come down from 150 per cent in 1991-92 to 40 per cent in 1997-98. In compliance with the WTO requirements, the basic customs duty has further been reduced to make it at world competitive level. The Union Budget 2007-08 has reduced the basic customs duty to 10.0 per cent. Average customs tariff rates, however, remain among the highest in the world. As per the World Development Indicator 2007, out of a set of 132 countries for which data on (simple) average customs tariffs were available, India had one of the highest average tariff rates (Table 5). In terms of weighted mean tariffs also (weighted by the country's trade with each of its trading partner), India has the highest tariff in terms of all products including manufactured products.

The collection rate indicates the incidence of customs duty and also levies/duties other than customs tariffs, which are not in the protective tariffs, viz., special additional duty on imports levied to offset the incidence of domestic trade taxes other than union excise duty borne by domestic producers, countervailing duty on import of goods meant to offset incidence of excise duty on similarly produced indigenous goods. It not only captures the element of protection due to customs duties but also the incidence of other duties/levies, which are in the nature of offsets to mitigate the impact of host of domestic levies for which producers cannot avail of any credit. Collection rates since the 1990s have declined substantially across all commodity groups in India. The most significant reduction in collection rates was observed in 'chemicals', 'man-made fibre' and 'metals' (Table 6).

Import duty collection rates in India remain one of the highest in the world. According to the World Trade Report 2003, (WTO), the ratio of duties collected to imports in India, even during the post 1990s, has been far higher than those levied by other comparable countries. The average import duties collection ratio was much lower at around 3 - 5 per cent in China, Malaysia, Indonesia, Korea and Thailand whereas in India, it was about 24.5 per cent in 1995-2000 (Table 7). As regards non-tariff barriers (NTBs), any levy other than customs duty or charges may be categorised as non-tariff barriers, which is generally grouped into: (i) import policy barriers; (ii) standards, testing, labelling and certification requirements; (iii) anti-dumping and countervailing measures; (iv) export subsidies and domestic support; (v) Government procurement; (vi) service barriers; (vii) lack of adequate protection to intellectual property rights; (viii) other barriers. Over the years, the NTBs applied by India have been drastically pruned. NTBs in the form of prohibited, restricted, canalised imports and imports requiring special import

license have been cut down and an increase in number of items have been put in the list of freely importable items (Table 8). Notwithstanding this cut in NTBs, India has one of the highest levels of NTBs among the EMEs. As per the WDI 2005, India had the highest ad valorem equivalent of NTBs at 3.2 per cent followed by Brazil at 2.4 per cent (Table 9). Taking into account various measures of openness, it is inferred that though India is increasingly becoming an open economy, it lags behind some of the EMEs owing to its higher tariff, import duty, and collection ratio and high level of NTBs.

B. Unit Labour Cost and Labour Productivity Another important indicator of competitiveness is the unit labor cost in manufacturing, since labour represents the most important non-traded input in manufacturing activity. Labour costs are also the most easily quantifiable, compared to the cost of capital. Unit labour cost (ULC) is defined as total compensation, C, per hour employed, H, divided by productivity, where the latter is measured as total output (O) per hour employed (Hooper and Larin, 1989). It could be represented as ULC = (C/H) / (O/H). A rise in a country's ULC relative to other countries leads to a decline in its competitiveness, which would translate into lower global market share. However, empirical evidence suggests that over the long-term, market share for exports and relative unit costs or prices tend to move together (Kaldor paradox). The central problem concerning inter-country comparisons of labour costs is how to translate the costs calculated for individual countries into comparable or common currency units. For the present analysis, the wage rate and ULC, as published in a research article by the Asian Development Bank, has been used. In terms of ULC, as in 2000, India had a competitive edge over Singapore and Korea (Table 10).

On comparing the unit labour cost of few commodities in some EMEs, it is found that except clothing, unit labour cost in India is higher in commodities like food products, textiles, electrical machinery and transport equipments (Table 11). In the case of food products, though unit labour cost in India has declined from 1.74 in 1980 to 1.29 in 2000, it is still higher as compared to other competitors. In textiles, unit labour cost in India not only increased during 1980-2000 but also remained high among some of the EMEs. The unit labour cost in case of electrical machinery though decreased during 1980-2000, it remained higher than Brazil, Indonesia, Philippines, Korea and Thailand. In transport equipment as well, unit labour cost has not only increased in India during the period but also remained the highest amongst these economies.

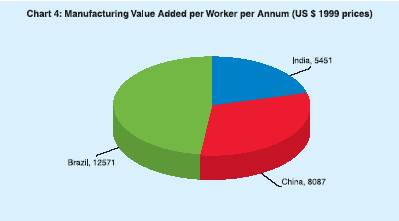

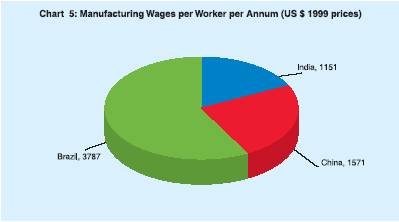

A comparison of annual wage rates in India with other EMEs reveals that it is much lower than that of Thailand, Singapore, Philippines, Malaysia and Korea (Table 12). However, as in 2000 annual wage rate in Indonesia was found to be much lower than that of India. Labour productivity in Indian industry is also found to be lower. The Investment Climate Survey data (Chart 4 & 5), show that the manufacturing value added per worker and

manufacturing wages per worker were lower when compared to China and Brazil. Nevertheless, India is fast catching-up with other economies as there have been impressive gains in labour productivity growth in the country. Labour productivity growth in India during 1995 to 2001 has all along been better than some countries like Korea, Philippines, China, Japan, Malaysia and Singapore, thus, indicating an increasing level of competitiveness vis-à-vis these economies (Table 13).

C. National Innovative Capacity International competitiveness increasingly depends on innovation. Local companies’ ability to acquire and deploy technology from around the world cannot sustain competitiveness over a longer period. With the erosion of traditional barriers to entry, competitiveness flows from the ability of companies in a nation to create and then globally commercialise novel products and processes and shift higher-up the innovation frontier as fast as rivals catch up. According to WEF, national innovative capacity is composed of four broad elements, viz., common innovative infrastructure, cluster-specific conditions, quality of linkages and company innovative orientation that define how location shapes the ability of a company to innovate at the global frontier. Overall, it is observed that there exists a strong co-relation between Innovative Capacity Index (ICI) and Business Competitiveness Index (BCI), with some exception. India’s ICI as in 2003 lagged behind Korea, Malaysia, and China. However, in terms of innovation in policy, linkages and strategy, India is ahead of China. In terms of innovative capacity, India also has a competitive edge over Thailand and Indonesia. On the whole, India’s weakness in innovative capacity highlights the fact that it has to put in strenuous efforts to transform from a low technology producer to a high technology cost effective producer (Table 14).

Section IV Commodity-wise Competitiveness of India’s Manufacturing Products India is one of the leading producers of a number of commodities in the world. India has been a leading producer of textiles, non-metallic mineral products, chemical and chemical products and basic metals amongst the developing countries. It is placed among the top-15 producers in the world in textiles, apparel, leather products, wood products, paper, chemicals, petroleum products, rubber products, non-metallic mineral products, basic metals, metal products, and transport equipments (Table 15). However, the country is facing close and stiff competition from a host of countries, including China, Korea, Singapore, Thailand, Malaysia, Brazil, Mexico, etc., for these commodities (Table 16). When we look at the commodity-wise labour productivity, it is observed that India has the lowest labour productivity among the select countries in the case of food products (Table 17). It is also observed that input and material cost remained the highest accounting for more than 88 per cent of total value of the output in India. The operating surplus remained the lowest – even less than 10 per cent of the total value of output. On the other hand, except Singapore, the operating surplus in case of other countries had been in excess of

one-fifth of the value of output. The higher input cost and lower operating surplus deter firms from exploiting economies of scale, which explains why India has not been able to emerge as one of the leading producers of food products. In the case of textiles, labour productivity in India remains low, while the input costs remains abnormally high, which, in turn, has eaten away the operating surplus margin. This again leaves India at a competitive disadvantageous position vis-à-vis Argentina, Malaysia, Mexico, Korea, Singapore, etc (Table 18). The Indian iron and steel industry is highly matured. Though, India is one of the leading producers of iron and steel, it has to improve its performance from its lower labour productivity and higher input cost (Table 19).

India compares favourably vis-à-vis other EMEs in the case of industrial chemicals (Table 20). Since the 1990s, labour productivity in chemical industry in India has improved, while the input and material cost has come down, leading to generation of higher operating surplus.

In the case of electrical machinery and transport equipments, India enjoys the advantage of lower labour cost. However, the competitive advantage is lost on account of higher input and material cost and lower operating surplus (Table 21).

India is having the advantage of low cost labour in respect of automobile parts and accessories. However, the labour productivity in India relating to automobiles is low while its input and material cost are high (Table 22).

In the last decade or so, merchandise trade in office machines and telecom equipments has expanded significantly. With the growing opportunity in trade in these equipments, some EMEs have taken advantage of this opportunity to expand their exports. In countries like Malaysia, Philippines and Singapore, such exports comprise about half of the merchandise exports. However, in India such exports accounted for only 1.1 per cent of total merchandise exports in 2006 (Table 23). The global trade in automotive components has also expanded very fast since the 1990s. India has made progress in the trade of automotive components as its share in total global exports of automotive products has increased from 0.06 per cent in 1990 to 0.32 per cent in 2006 (Table 24). Nevertheless, India’s share in global

exports of automotive products is very less as compared to Brazil, China, Mexico, Korea and Thailand. Against this backdrop, it is observed that across a variety of commodities, as compared to other economies, mainly Asian countries, Indian manufactured products suffer from lower labour productivity, higher inputs and materials cost, lower operating surplus, despite having one of the lowest labour cost. Higher input cost in India is attributable to cascading effect of indirect taxes on selling prices of commodities; higher cost of utilities like power, transport and high transactions costs. Multiplicity and high level of taxes, high cost of capital and poor quality and excessive user charges of support infrastructure services impose additional costs to the tune of 12.2 per cent of the cost of production (FICCI, 2005). Higher input and material costs account for a major part of the value added thereby rendering the lower labour cost advantage of the economy ineffective. Lower operating surplus leaves little incentive for industrialists to expand their capacity and grow big. At the same time, it is found that India’s share in trade of those commodities, which are traded the most in the world such as office machines and telecom equipments, automotive components, and other machinery and transport equipments, is very low. Nevertheless, there exists substantial opportunities for India to expand its global share in exports of these commodities. Section V Issues to be Addressed in Boosting up India’s Manufacturing Sector Competitiveness Indian manufacturing industries have certain inherent strengths and advantages in having a relatively inexpensive, adequate and skilled labour force, cost-effective and competitive prices of goods produced, large manufacturing base and proximity to fast growing Asian markets. In general, India has one of the largest pool of scientists and engineers, thereby giving the country a competitive edge in pursuing R&D activities. Furthermore, the presence of a number of high quality R&D institutions also imparts a competitive edge. Some of the manufacturing industries have their own sector specific inherent strengths when compared to other economies. With its cheap and skilled labour force and impressive design expertise, India stands a better chance in expanding its textile exports. Abundant supply of quality raw material will enable the Indian textile industry to produce quality consumer products at a competitive rate. In pharmaceuticals, the success stories of Indian companies combining two very unique Indian characteristics: a large pool of talented chemists and good entrepreneurial ability augur well for its growth. A sizeable export business of US $ 350 million has already been built in active ingredients for generic drugs and formulations. With the rise of the Indian

firms at the international level, it is argued that Indian companies have some

key fundamental strength that will help them dominate not just their domestic

markets, but parts of the global market as well. India is no longer seen as a

laggard and the country is now well on the road to become the world’s favourite

destination for outsourcing for R&D, engineering design, telecommunications,

super-specialty healthcare and a manufacturing hub for high technology products.

India is among the world leaders in the production of textiles, non-metallic mineral

products, basic metals, etc., and steadily capturing the world export markets

in the services like software exports, BPO, ITES, in addition to pharmaceuticals. Furthermore, the National Manufacturing Competitiveness Council (NMCC) was set up in September 2004 to provide a continuing forum for policy dialogue to energise and sustain the growth of manufacturing industries. As a first step towards developing a strategy for manufacturing growth, a Strategy Paper on "National Strategy for Manufacturing" was prepared by the NMCC, which attempted to identify the key policy initiatives to make the Indian manufacturing become competitive to realise higher level of growth and employment in the country. The NMCC has identified certain deficient areas, which require immediate attention and policy initiation not only from the Government side but also from other stake holders like firms, industrial associations, trade bodies, etc., to attain the required growth in the manufacturing sector. The Investment Commission has been constituted to find out ways and means of attracting certain level of secure investments. The Commission will make recommendations both on policies and procedures to facilitate greater FDI flows into India. A High Level Committee on Manufacturing was constituted in April 2006 with the Prime Minister as the Chairman. The Committee would address macroeconomic issues impinging on the growth and competitiveness of the manufacturing sector in India, and create a policy framework for necessary reforms covering all the aspects of manufacturing competitiveness. The Committee would also ensure coordination among the various Ministries which deal with manufacturing sub-sectors and review the implementation of time-bound action plans to achieve the objective of 12 per cent growth in manufacturing sector. The Committee would initiate steps to make India a manufacturing hub for areas having potential for global competitiveness such as textiles, automobiles, leather, food processing, steel, metals, chemicals and petroleum products. This is a positive step towards encouraging manufacturing sector growth, which would improve the competitiveness of the Indian manufactures. Despite these institutional developments to boost the India’s manufacturing competitiveness, India’s comparative performance vis-à-vis some of the EMEs is low due to various reasons as seen in the earlier sections. There is a need to address the following important issues appropriately to improve the competitiveness of the Indian manufacturing sector. Further Diversification of Manufacturing Export Basket It has been found that the manufacturing exports accounted for about 70 per cent of the total exports of the country. Of which, five sectors, viz., gems and jewellery, textiles and garments, engineering goods, chemicals, leather and leather goods alone accounted for over 68.0 per cent of India’s exports (Table 25). While India’s manufacturing sector exports have shifted from leather and textiles to chemicals and engineering goods over the years, there appears to be considerable scope for further diversification of manufacturing sector exports and concentrate on high value manufactured goods to further improve its competitiveness.

Improvement in Export Quality Poor quality of products plays a crucial role in determining export competitiveness of an economy. In terms of export quality indices provided by the UNIDO2 , India does not fare well and significantly lags behind many of the EMEs such as China, Thailand, Philippines, Malaysia and Singapore (Table 26). Improvement in Productivity As observed earlier, labour productivity in respect of many of the manufacturing goods in India is very low when compared to other EMEs. The need of the hour is to identify fast-track industries on the basis of comparative advantage or raw material availability or process capabilities or local product development capability or specific skills

or a combination of these and encourage them to achieve better competitiveness. Change in productivity can come by introducing and entrenching Total Productive Maintenance (TPM) process in every business activity. The essence of TPM is business process improvement through working teams and cutting across organisational layers, which yields significant benefits. Concerted efforts could be made to disseminate the concept and its implementation. Increase in Technology Intensity Technology intensity of exports is another factor determining competitiveness of the manufacturing sector exports of an economy. India’s manufacturing exports largely comprise low-technology induced goods. High-technology exports, according to World Bank, are products with high R&D intensity in aerospace, computers, pharmaceuticals, scientific instruments, and electrical machinery. In the world trade where primary products and resource-based manufactures have steadily lost their importance, high technology exports are the largest foreign exchange earners for various countries. In India, though ITES is considered as the main driver of growth, the share of high-technology items in its exports as compared with other EMEs is one of the least - about one-sixth of that of China (Table 27).

High technology exports in the case of India constituted only 4.9 per cent of total manufacturing exports in 2004. The low level of technological sophistication of India’s exports undermines its competitiveness. Research and Development Efforts Science and technology sheds light on countries’ technological base - the availability of skilled human resources, the competitive edge the country enjoys in high-technology exports, sales and purchases of technology through royalties and licenses, and the number of patent and trademark applications filed. India lags behind a number of economies in terms of manpower for research and development as well as efforts towards R&D (Table 28). Improvement in Business Environment Countries differ widely in their business environment. In some countries the process is straightforward and affordable, while in others

it is complex and costly. The World Bank uses some key indicators in order to measure the ease or difficulty of operating a business -starting a business, hiring and firing workers, registering property, getting credit, protecting investors and enforcing contracts. When entrepreneurs start a business, the first obstacle they face is the administrative and legal procedures required to register the new firm. According to the World Bank’s indicator, in India, entrepreneurs have to go through 11 steps to launch a business over 35 days on an average, at a cost of 73.7 per cent of per capita income, compared with the region’s average of 8 steps, over 33 days on average, at a cost equal to 46.6 per cent of per capita income (Table 29). Thus, India does not enjoy a favourable business environment vis-à-vis other EMEs, which calls for policy intervention. Removal of Infrastructure Bottlenecks India’s weak infrastructure, especially of export infrastructure in the ports, congestion problems, insufficient bulk terminals, etc.,

needs to be improved/rationalised. High cost of power with restricted and unreliable supply affects the industrial performance. Space is a major constraint in big cities. Therefore, more industrial estates in the rural and semi-urban areas with required basic infrastructure facilities are the need of the hour. Transport infrastructure - highways, railways, ports and waterways, airports and air traffic control systems - and the services that flow from them also determines the efficiency in the movement of goods and services in the economy. The higher efficiency reduces the transportation cost, thereby giving a competitive edge to the economy. Railway sector in India is one of the largest in the world. Nevertheless, employee productivity of railways in India is very low as compared to China, Korea, Brazil, Indonesia, etc. Similarly, port container and air freight traffic is also very less in India as compared to other Asian economies except Philippines (Table 30). Inadequate transport infrastructure undermines the competitiveness of Indian economy vis-à-vis its competitors. New

initiatives for encouraging entry of more private sector participation and public-private partnership (PPP) in important sectors like electricity distribution, aviation, roads, railways, ports and airports should be explored. The experience in privatising the PSUs in the infrastructure sector has been very encouraging. Privatisation will not only enhance efficiencies and bring down costs, but also generate more earnings, in addition to the annual revenue streams for Government. Encouragement for more PPP in infrastructure development would improve the infrastructure in the country, which would in turn increase the export competitiveness. Legal and Regulatory Environment Multiplicity of laws and frequent amendments restrict and create impediments in the way of growth and necessitates a need for unified laws to lessen the grey areas in the policy environment. Procedural hurdles need to be liberalised. Furthermore, complicated taxation laws and procedures come in the way of consolidating/ restructuring the industrial units due to the concessions that hitherto availed by them. Adoption of uniform tax laws could facilitate fair competition and growth. The Government’s endeavour to reduce the central sales tax rate in recent time is an effort in the right direction. There is a need to address the policy and institutional barriers, which impede growth in manufacturing. Furthermore, myriad laws and regulations that govern the manufacturing sector need to be pruned down and replaced with simplistic laws. Liberalisation of Labour Laws The economic reforms that started in the 1990s have left the labour market untouched, which has led to various problems such as lower productivity, inefficient allocation of resources, etc. Rigid labour laws have resulted in underinvestment in some industries such as textile industry. India’s inflexible labour law is not market driven; thus, the problem of unskilled labour and its low standard reduces the competitiveness of the country. Simplification of laws relating to retrenchment, and replacement of non-performing workers at a time when the unit is in trouble could enable the reorganisation/ consolidation in the industry. So, it becomes important that labour reforms be carried out in order to accelerate investment, enhance productivity, competitiveness and employment generation in the economy. SME Sector related Issues Historically, India has had a highly fragmented industrial structure. The manufacturing sector in India is characterised by a significant number of small scale and unregistered manufacturing firms. The Small and Medium Enterprises (SMEs) sector in the Indian economy has been a very vital organ and it has a share of over 40.0 per cent of the gross industrial value added in the economy. About 44 per cent of the country’s exports directly or indirectly pertain to this sector. Given its contribution in the export basket of the country, improvement of competitiveness of the manufacturing sector is not possible without paying adequate attention to the SMEs. Small Scale enterprises in India have received significant preferential treatment – both in terms of specific sectors being reserved exclusively for them and in terms of preferential excise and other fiscal concessions. Since the preferential treatment is contingent on these units remaining small, there is no incentive for these units to expand eroding the competitiveness of Indian manufacturing. This has prevented India’s market size from being translated into scale for manufacturing. Industry – research institute interaction is low in India, thereby reducing the chances of creation of commercially viable technologies. India’s huge potential lies in the SMEs to expand employment opportunities, further develop the industry and boost the exports. But, there is no broad-based market information network to coordinate and develop the SME sector. There is an urgent need to develop more industrial clusters to facilitate better information network among the SMEs. Unavailability of information on the reliability of potential buyers and sellers tends to increase transaction costs. There is significant scope for improving productivity levels in different manufacturing industries through cluster approach. On the lines of identified SSI clusters, clusters may also be identified for other manufacturing sector with improved infrastructure facilities that may improve the competitiveness of the industries. At present, about 114 commodities are reserved for exclusive manufacturing by the SSI sector. Production of some of these items requires modernisation and technology upgradation to achieve economies of scale and de-reservation alone would help enhance competitiveness of these products. Removal of all restrictions on investment in labor-intensive small-scale industries needs to be done. The control has led to various sets of inefficiency in these industrial sectors. There is a need for improving appropriate linkages with education, infrastructure, human and natural resources and environment for long-term sustainable development and facilitating value-addition and self-reliance approach towards manufacturing. Sector Specific Issues Lack of strong patent protection is a deterrent to attract sizeable investment in R&D, foreign direct investment (FDI) and introduction of newer and better products in the drugs and pharmaceuticals industry. Deferred or delayed payments, non-availability of power, and lack of orders/demands are problems plaguing most of the sugar industry, which needs to be addressed urgently. High tariff barrier coupled with stringent sanitary and phyto-sanitary measures, including animal health and residues of contaminants by the export destination countries like Europe and the US affected the domestic production and export competitiveness of the India’s milk products. India’s low quality and low technology intensity of exports are more vulnerable in the competitive environment, which needs to be improved with quality products and the share of high technology intensity exports to be increased. Basic infrastructure, particularly transport infrastructure is vital for any products to compete in the market, which needs to be improved to attain cost competitiveness. Business environment also needs improvement by eliminating procedural hurdles to attract more investment in the manufacturing sector, particularly FDI. Section VI Concluding Observations As seen earlier, the competitiveness of the Indian economy has been improving on the whole, so has the competitiveness of manufacturing sector. Sharp rise in the share of manufacturing exports in GDP since the 1990s bears testimony to this. India’s manufacturing sector is becoming increasingly integrated with the global economy as we found that the world GDP was positively affecting India’s manufacturing exports. India is found to be one of the leading producers and exporters in respect of various commodities as also the country enjoys significant advantages in terms of lower labour costs as compared to other EMEs. However, our analysis brings out that India’s performance in the manufacturing sector is not so impressive as that of other comparable EMEs. This could largely be attributable to lesser export-orientation coupled with low technology exports of Indian manufacturing sector. Given the urgent need to improve competitiveness, one cannot refrain from being prescriptive. It is found that India is concentrating largely on exporting processed goods such as gems and jewellery and petroleum products, which have high import content. This is reflected in sharp increase in the share of petroleum products in India’s exports during the recent years, which has increased nearly ten fold from 1.4 per cent in 1995-96 to 14.8 per cent in 2006-07. On the contrary, the share of traditional export items such as leather, textiles, etc., has declined over the years. Aganist this backdrop, there is an urgent need for further diversifying India’s export basket towards high value goods such as office and telecom equipments, high technology goods, etc., to improve India’s competitiveness. Furthermore, India needs to rationalise the tariff and non-tariff barriers in order to sharpen its competitive strength. Ultimately, the issues relating to poor export quality, infrastructural bottlenecks, lower efforts at research and development that have taken a toll on the country’s competitiveness should be addressed from a holistic perspective. There should be widespread awareness and concerted efforts among the constituents of the manufacturing sector and decision making layers about the need to achieve sustained increase in Indian manufacturing sector’s competitiveness, which is not a discreet event but a continuous saga. Notes: 1 China

is not included due to non-availability of information. Select References Asian Development Bank (2003), ADB India Economic Bulletin Vol.I, No. 4, December, Asian Development Bank, Indian Resident Mission, New Delhi. — (2003), ADB India Economic Bulletin Vol.II, No. 3, December, Asian Development Bank, Indian Resident Mission, New Delhi. — (2004), Asian Development Outlook, Manila, Philippines: Asian Development Bank. Banga, Rashmi and Bishwanath Goldar (2004), Contribution of Services to Output Growth and Productivity in Indian Manufacturing: Pre and Post Reforms, Working Paper 139, Indian Council for Research on International Economic Relations, New Delhi, July. Bhattacharjee, Aditya (2004), Trade and Competition Policy, Working Paper No. 146, ICRIER, New Delhi, November. CII-Word Bank (2002), Competitiveness of Indian Manufacturing: Results from a Firm-Level Survey, Omkar Goswami, A.K. Arun, Srivastava Gantakolla, Vishal More, Arindam Mookherjee, Confederation of Indian Industry (CII) and David Dollar, Taye Mengistae, Mary Hallward-Driemier, Giuseppe Iarossi, The World Bank (WB), January. Cook, Paul; Colin Kirkpatrick; Martin Minogue and David Parker (Ed. 2004), Leading Issues in Competition, Regulation and Development, Edward Elgar Publishing Limited, Cheltenham, UK. Dominic Wilson and Roopa Purushothaman (2003), Dreaming with BRICs: The Path to 2050, Global Economics Paper No: 99, Goldman Sachs, October. Federation of Indian Chambers of Commerce & Industry (2005), Manufacturing Sector In India: Competitiveness and other Issues, January. Felipe, Jesus and Grace C. Sipin (2004), Competitiveness, Income Distribution, and Growth in the Philippines: What Does the Long-run Evidence Show? ERD Working Paper No. 53, Asian Development Bank, Manila, Philippines, June. Goldar, Bishwanath and Suresh Chand Aggarwal (2004), Trade Liberalisation and Price-Cost Margin in Indian Industries, Working Paper No. 130, Indian Council for Research on International Economic Relations, New Delhi. Golder, Bishwanath (2004), Productivity Trends in Indian Manufacturing in the Pre-and Post-Reform Periods, Working Paper No. 137, ICRIER, New Delhi, June. Heng, Toh Mun and Tan Kong Yam (1998), Competitiveness of the Singapore Economy: A Strategic Perspective, Singapore University Press, Singapore. Hooper, Peter & Larin, Kathryn A. (1989), International Comparisons of Labor Costs in Manufacturing, Review of Income and Wealth, Blackwell Publishing, Vol. 35(4). International Institute for Management Development, World Competitiveness Yearbook, Various issues, Lausanne, Switzerland. Joshi, V. and I.M.D. Little (1994), India: Macroeconomics and Political Economy 1964-1991, Washington, DC: The World Bank and Oxford University Press. Kumar, Nagesh (2001), India’s Trade in 2020: A Mapping of Relevant Factors, A paper prepared for the Committee on Vision 2020 for India, Planning Commission, Government of India, Research and Information System for the Non-aligned and Other Developing Countries, New Delhi, May. Lall, Sanjaya (1999), India’s Manufactured Exports: Comparative Structure and Prospects, World Development 27(10): 1769-86. Mahadeva, Renuka (2002), New Currents in Productivity Analysis: Where To Now? Productivity Series 31, Asian Productivity Organisation, Tokyo, Japan Mathur, Archana S. and Arvinder S. Sachdeva (2005), Custom Tariff Structure in India, February 5, 2005, Economic and Political Weekly. OECD (2001), OECD Productivity Manual: A Guide to the Measurement of Industry-level and Aggregate Productivity Growth, Statistics Directorate, Directorate for Science, Technology and Industry, Paris. OECD. Panchamukhi, V.R. (2000), World Trade Organisation and India: Challenges and Perspectives, RIS Discussion Paper # 01/2000. Singh, Ajit (2004), Multilateral Competition Policy and Economic Development: A Developing Country Perspective on the European Community Proposals, UNCTAD Series on Issues in Competition Law and Policy, New York And Geneva: The United Nations. Srinivasan, T.N. (1998), India’s Export Performance – A Comparative Analysis in Ahluwalia, I.J. and I.M.D. Little (Eds.) India’s Economic Reforms and Development: Essays for Manmohan Singh, New Delhi, Oxford University Press. Suresh, M. Padma, (2004), Strategic Approach to Strengthening the International Competitiveness in Knowledge Based Industries: Non-electrical Machinery Industry, RIS Discussion Paper # 81/2004, September. UNCTAD (2004), Handbook of Statistics 2004, New York And Geneva: The United Nations. — (2004a), Trade and Development Report, 2004, New York And Geneva: The United Nations. UNIDO (2004), Industrial Development Report 2004, Vienna, Austria: The United Nations Industrial Development Organisation. — (2004a), UNIDO Annual Report 2004, Vienna, Austria: The United Nations Industrial Development Organisation. Virmani, Arvind (2004), Sources of India’s Economic Growth: Trends in Total Factor Productivity, Working Paper 131, Indian Council for Research on International Economic Relations, New Delhi, July. Viswanadham, Prof. N. and Dr. Roshan Gaonkar (2003), Leveraging Logistics to Enhance Indian Economic Competitiveness, CII Logistics 2003 Theme Paper, The Logistics Institute – Asia Pacific, Singapore. Wilson, Dominic and Roopa Purushothaman (2003), Dreaming With BRIC: The Path to 2050, Global Economics Paper No: 99, October 2003, Goldman Sachs. World Bank (2005), Global Economic Prospects: Trade, Regionalism, and Development, Washington, DC: The World Bank. — (2004), India: Investment Climate Assessment 2004 - Improving Manufacturing Competitiveness, Finance and Private Sector Development Unit, South Asia Region: The World Bank, November. World Economic Forum, Global Competitiveness Report, various issues, WTO (2005), International Trade Statistics 2005, Geneva: World Trade Organisation. Yap, Josef T. (2004), A Note on the Competitiveness Debate, Discussion Paper Series No. 2004-39, Philippine Institute for Development Studies. * L. Lakshmanan, Assistant Adviser; S. Chinngaihlian, Research Officer and Raj Rajesh, Research Officer are in the Department of Economic Analysis and Policy of the Reserve Bank of India. The authors are extremely thankful to Shri K.U.B. Rao, Adviser for his encouragement and valuable suggestions. The authors are also thankful to an anonymous referee for comments on the earlier draft. The authors are also thankful to Shri A.B. Umaria and Smt. S.S.Walavalkar, Sr. Assistants, for providing the necessary data assistance. The views expressed are of the authors' own and the usual disclaimer applies. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

പേജ് അവസാനം അപ്ഡേറ്റ് ചെയ്തത്: